QAC Automotive and Robotics (QAaR) Quality Assurance

FOCUSED ON THE FUTURE

Welcome to the fourth edition of the QAaR newsletter. In this edition, we’ll focus on sharing more information about automotive technology and current projects the QAC team is working on. We will be presenting how QAC provides an extensive Quality Assurance diagnostic of our customers robotic software ensuring quality, functionality and safety.

Keeping you informed

Our automotive and robotics quality assurance workstreams

Robot Vehicle Quality Assurance

In the last few years, the robotics field has experienced staggering growth. Numerous think tanks predict exponential growth within this market. Large and robotic based businesses alike are flooding the market, all with the same goal in mind. to release their robotics into production. We have identified a business need to ensure robots meet functional and safety requirements when interacting with humans or vehicles in a real-life environment. Our QAaR (QA Consultants Automotive and Robotics) team have built a solution to assist potential customers with the following:

ROBOTS COMPONENTS

Robotics is broken down into three main components:

- Electrical Engineering

- Mechanical Engineering

- Software Engineering

-

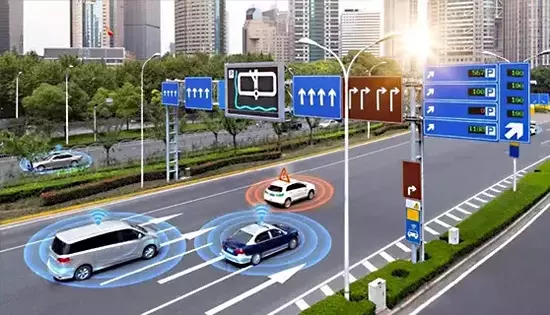

Running thousands of tests under different conditions

Using our simulated test framework, we can perform thousands of tests under different safety, environmental and emergency situations within a few days that would take months, or even possibly years to test in real life. We can identify potential issues and failures quickly and advise our customers for improvements and focused physical acceptance testing. -

Customized for our customers’ needs

There are many different types of robots each performing different functions. We can customize our test case coverage to include, but not limited to, the following: human interaction, indoor / outdoor conditions, weather, lighting, electrical interference e.g. EMI and unique terrain and traction situations. -

Prioritization of tests using ISO 26262, 13849, & IEC 62061

Our test case prioritization process follows industry standards for both road and robotics standards to ensure our customers are focused on critical systems and can communicate to their clients that they are aware and following best testing practices.

At QAC, we employ testing methods from a Software Engineering perspective. We leverage this knowledge to build a simulated testing model environment to execute 1000s of test cases that incorporate obstacles with terrain, environmental, and emergency conditions. This type of testing incorporates industry safety standards to ultimately prove the robot is “Fit for Use”.

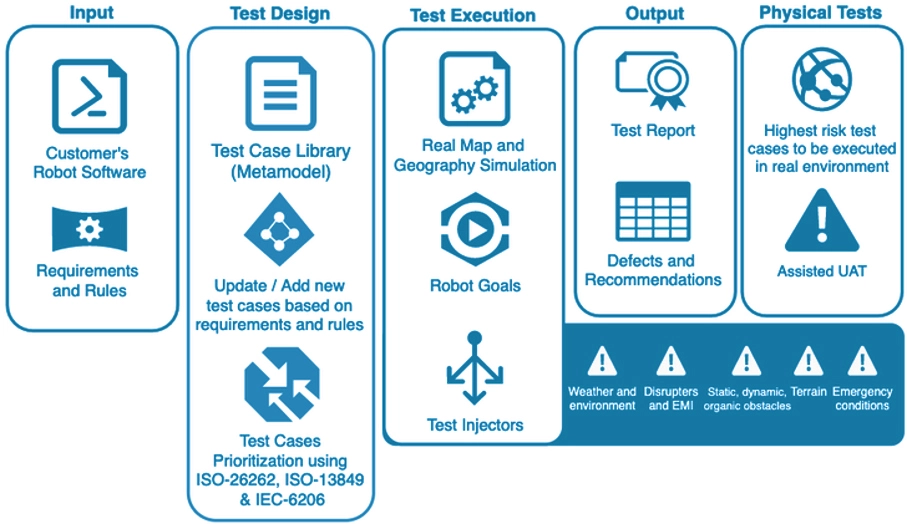

Robotic Vehicle Automation Framework

Like traditional QA, we start off with a set of requirements and rules which are provided by the customer. In turn, these standards are used for the basis of our expected results. Using QAC’s meta-model we create a set of model-based tests. These tests are easily updated as new requirements or rules occur. Based on industry safety standards, QAC executes tests based on a prioritization score of each test case. Using Robotic Operating System (ROS) and Gazebo (in conjunction with other tools) we then build a simulated environment. This system houses the customers’ robot software and calls upon generated test cases to be executed. Not only can we perform these base tests, but we have 100s of combinations of test injectors to perform more robust testing.

-

Weather and Environment

Light, rain, snow, fog, wind, traction water, ice, sand, etc. -

Terrain

Incline, decline, uneven ground, and holes -

Disrupters and Emergency conditions

EMI, smoke and fire -

Static and Dynamic Obstacles

People and crowd gathering dispersing, other moving objects and vehicles, furniture, equipment, walls, and entrances, transparent and reflective obstacles (glass)

With our automation framework, we can execute all tests automatically. Leveraging our cloud computing, we can run our tests and conditions in parallel to maximize test execution and highlight where potential issues are found.

Benefits of QAC’s Robot Vehicle Automation Framework

By Using QAC’s Robot Quality assurance approach, we provide our customers the following benefits:

-

Decrease in probability of hardware failure

By conducting thousands of tests in a short period of time we can determine where possible hardware failure lies. These tests can save our clients both time and money to improve their robot functionality while avoiding the probability of hardware failure -

Decrease in probability of occurrence and harm

By following industry ISO standards, we can prioritize our tests to factor in the probability of the occurrence of harm to human interactions. This has proven to be an important selling point to our customers as they in turn show their clients the interactions between their robots and humans -

Test Scenarios and Requirement Improvements

All recommendations listed out in the report are based on requirement gaps where functional and safety scenarios are missing and not handled by the robot system. Our meta-model covers a long list of weather, environmental conditions, terrain situations, disrupters and emergency conditions, and different types and sizes of static and dynamic objects through test injectors that allow the identification of scenarios and situations where the robot vehicle does not behave properly, or does not make a proper action or decision. -

Faster time to market

As the robotic community grows, the competition grows. Those first to market can provide a safe, quality product much faster than their competitors -

Re-execution and Regression Testing

With all defects and requirements gaps identified, our clients are able to address them according to a list of priority based on international standards and run a second round of tests to ensure all fixes and improvements have been properly executed. -

Leveraging ACE

Because of our close relationship with the Automotive Center of Excellence (ACE), we can provide our customers a controlled weather environment that mimics “real life” physical acceptance testing

REPORT

Once testing is complete, an automatically generated test report shows executed tests, pass, or fail. Additionally, detailed requirement gaps and recommendations are provided.

STAY TUNED

Our partners: